Innovation

Research & Development

We apply state-of-the-art analysis and simulation techniques to optimize existing forming processes and review the feasibility of newly developed processes. We also use simulation techniques with substitutes for machined products.

Our

own

TECHNOLOGY

The process we have internally designed and developed

for the production allows our transfer presses to achieve

a deep drawing of the parts starting from strip.

The production has never been so fast!

Productivity

Our high-performance equipment and advanced software increase daily productivity over other conventional production lines.

Wastes

Invernizzi Presse is able to offer the best option

for waste optimization with the possibility to provide

also customized solutions.

Get the most out of the least!

ENERGY EFFICIENCY

Optimization of the production process with no intermediate treatments or cost of fluid disposal.

BENEFITS OF

OUR EXCLUSIVE

TECHNOLOGY

Thanks to the Invernizzi Presse’s cutting-edge technology you will be able to make various range of product, allowing you to obtain maximum precision with more rationalized production costs.

RELIABILITY

Reducing the number of necessary machines significantly means reducing the risk of anomalies and/or malfunctions. The top quality standard of Invernizzi presses is an added value in terms of reliability.

PRODUCTION TIMES

Less machines needed for each production resulting

in a major rationalization of manufacturing times.

Innovation

Always keeping up with the times; all of our machines can be integrated in a 4.0 environment.

next generation of flexibility

for product design

Siemens NX software is a flexible and powerful integrated solution that helps you deliver better products faster and more efficiently. NX delivers the next generation of design, simulation, and manufacturing solutions that enable companies to realize the value of the digital twin.

Supporting every aspect of product development, from concept design through engineering and manufacturing, NX gives you an integrated toolset that coordinates disciplines, preserves data integrity and design intent, and streamlines the entire process.

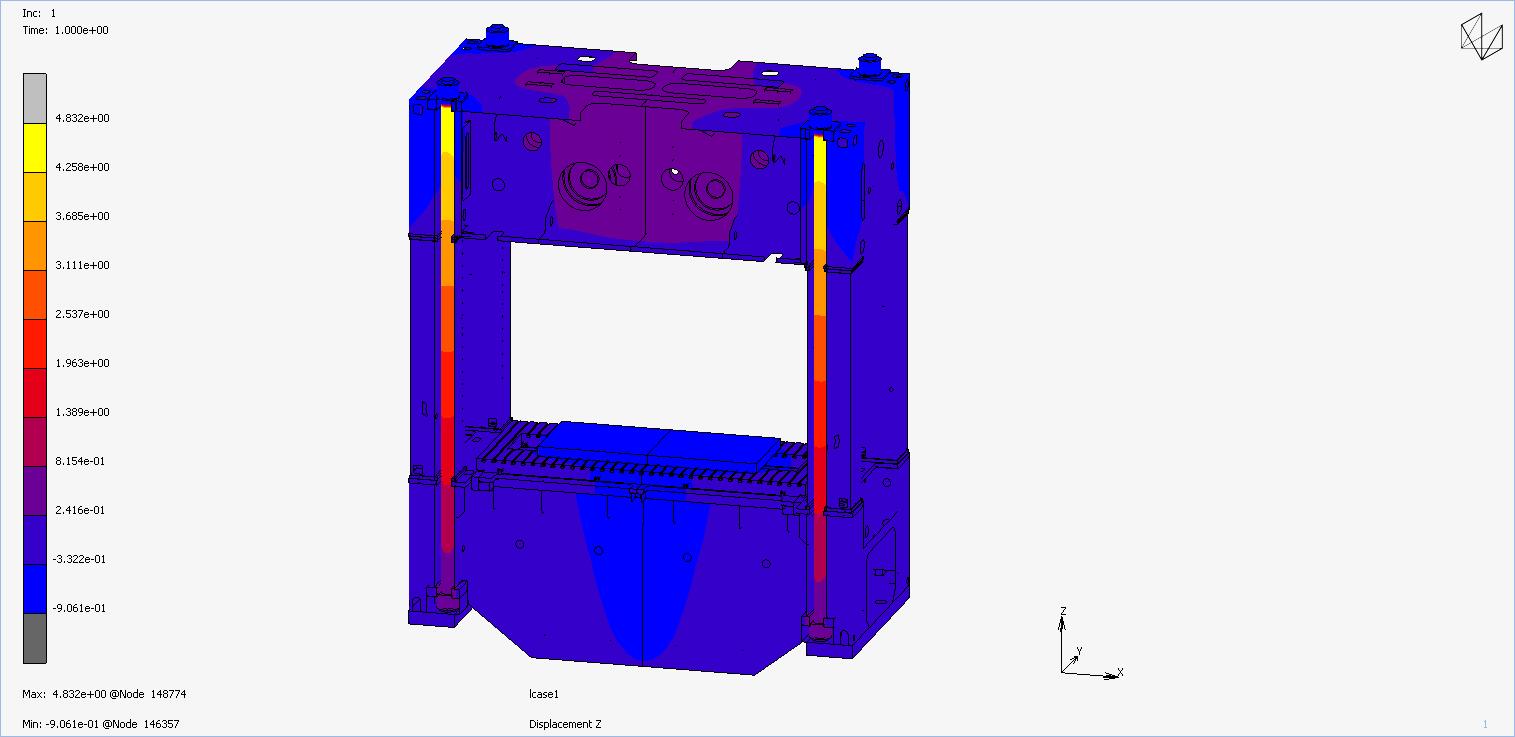

ANALYSIS OF STATIC ELEMENTS

Patran is the world's most widely used pre/post-processing software for Finite Element Analysis (FEA), providing solid modeling, meshing, analysis setup and post-processing for multiple solvers including MSC Nastran, Marc, Abaqus, LS-DYNA, ANSYS, and Pam-Crash.

Patran provides a rich set of tools that streamline the creation of analysis ready models for linear, nonlinear, explicit dynamics, thermal, and other finite element solutions.

Patran's comprehensive and industry tested capabilities ensure that your virtual prototyping efforts provide results fast so that you can evaluate product performance against requirements and optimize your designs.

KINEMATIC AND DYNAMIC ANALYSIS

Msc Adams Machinery empowers to put data to work throughout the product manufacturing lifecycle, digitally transforming operations to improve productivity and efficiency while embedding quality throughout the process.

This technologies enable manufacturers to access, analyse and actively leverage data from all key stages of the manufacturing process to empower better decision-making.

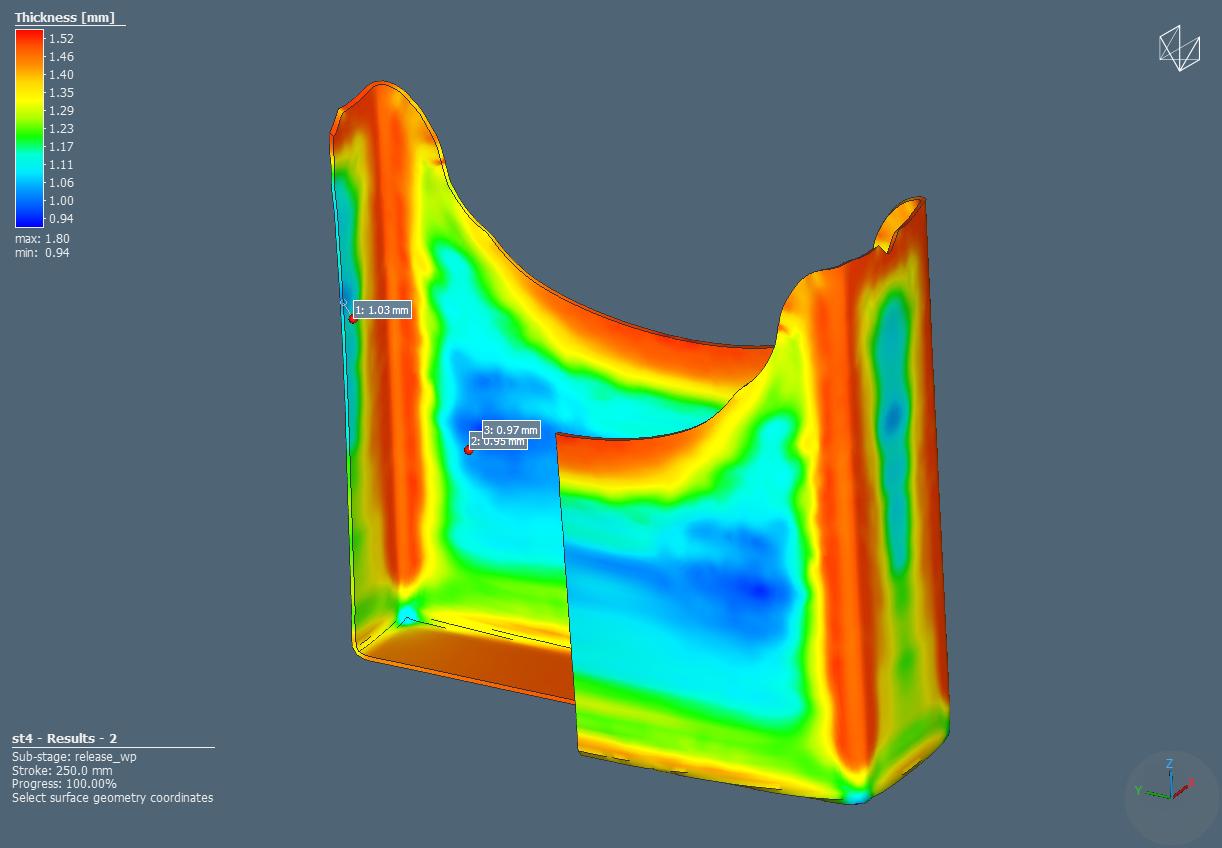

ANALYSIS AND SIMULATIONS OF STAMPING PROCESSES

Simufact software solutions cover a large number of metal working and metal processing production processes.

The processes are grouped to application groups Forming, Joining, and Additive Manufacturing.

These 3 application groups include areas of application of software solutions Simufact Forming, Simufact Welding, and Simufact Additive and guarantee tech optimization of production processes and how our software solutions can help him with these tasks.

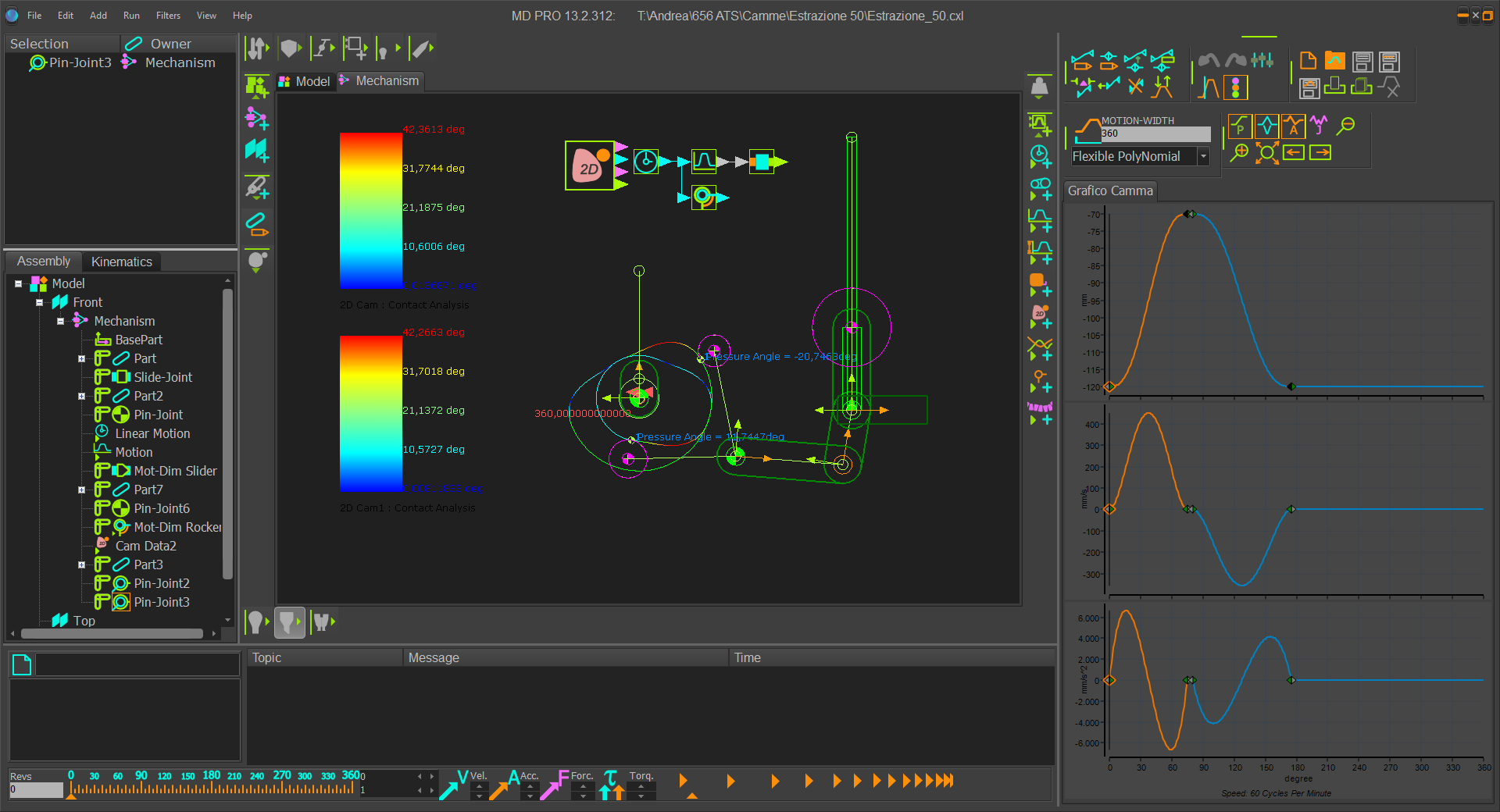

SOFTWARE FOR MODELING MULTI-AXIS CAM MACHINES, MECHANISMS, AND MOTION DESIGN

PSMotion Ltd is the the best software for cam, mechanism, and motion design of multi-axis machines.

Featured products

MSC ADAMS helps put data to work to improve productivity and efficiency while embedding quality throughout the product lifecycle.

It technology enables manufacturers to access, analyse and actively use data from all the key stages of the manufacturing process. Through an unparalleled portfolio of digital manufacturing technologies spanning CAE solutions for design and engineering, CAD CAM and complementary software for production applications, metrology hardware and software solutions, as well as data management and analytics tools, empower users throughout the process with deep and actionable insight into product quality, ensuring that quality drives productivity.

Featured products

MSC Marc is a nonlinear finite elements analysis software used to simulate behavior of complex materials and interaction under large deformations and strains. It can also simulate multi-physics scenarios across structural, thermal, piezoelectric, electrostatic, magnetostatic, and electromagnetic behaviors. It uses automatic two-dimensional and three-dimensional remeshing to analyze structures undergoing large distortions, and crack propagation.